This weekend, world leaders will meet in Egypt for the start of the COP27 climate change summit. It’s the 27th annual meeting of the “Conference Of the Parties” who signed up to the UN climate agreement in 1992 (in other words, the world has been meeting to discuss climate change for more than 30 years). This year’s focus will be on reducing carbon emissions, whilst also recognising that developing countries suffer the most from their impact.

Such lived experiences can seem far removed from daily life here at our factory in Plymouth, yet it is a timely reminder that we are all part of this global issue, so must play our part in making a difference (which, by the way, is one of our corporate values).

As a company, we made our own commitment last November to achieve Carbon Net Zero by 2040, and hopefully sooner. You can read the first part of our Carbon Net Zero story here, which reflects on the first six months.

So, what have we achieved since?

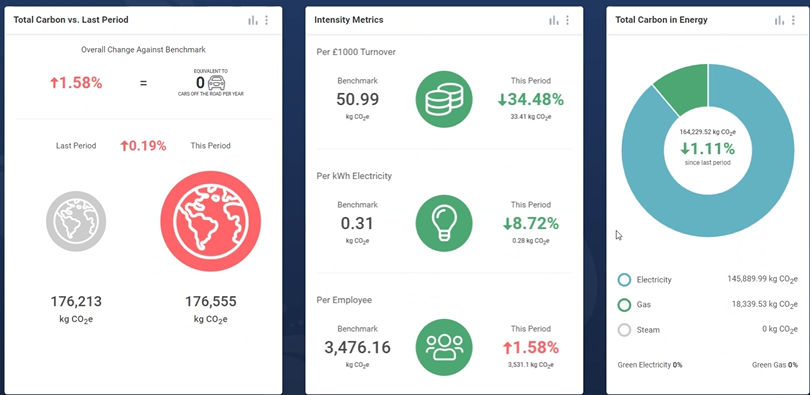

Firstly, our carbon footprint dashboard continues to measure the impact of our activities, and we now have several months of data to use as a benchmark. It’s been a busy and productive six months at Aldermans, with increased productivity, and revenues soaring by 60%. So to see that our carbon emissions have only increased by 1.58% overall, compared to the previous year, feels like a respectable result. It’s a reminder that figures must always be put into context, and that financial and emissions growth don’t necessarily go hand in hand.

Of course, by far the greatest challenge at present is the stratospheric rise in energy costs. While this is a Scope 2 issue, the scale of the increase has propelled this high up our list of priorities.

We negotiated a new fixed-term energy contract back in June; and although the rate felt high back then, we know that wholesale prices have since escalated further. Consequently, the government’s Energy Bill Relief Scheme probably won’t benefit us greatly – but we know it will help lots of other small businesses, even if it’s only for an initial six-month period.

Still, in October we found ourselves facing an energy bill which had tripled. Annually, it’s set to jump from £90,000 to £240,000 per year. Even the most modern machines in our factory guzzle electricity!

However, we are able to benefit from a partial exemption from the Climate Change Levy (a tax on business energy use), due to the nature of some of our manufacturing processes. It’s well worth all manufacturers exploring where they might be eligible for some reductions – every little helps!

When we renegotiated our energy contract, we made the decision to switch to a ‘green tariff’. It made sense financially, and also means that our carbon footprint will immediately drop by 90%, which is good news for the dashboard!

Nonetheless, the more we can take control of our own energy generation, the more resilient we will be for the future, and less susceptible to energy market changes. (This reminds me of the early years of Aldermans, when my parents bought a generator to keep the factory running during the 1970s blackouts!).

Plans are now underway for us to increase the size of our rooftop solar array, and generate at least some of our own electricity needs. While the investment is likely to be in excess of £200,000, at current rates the payback time will be less than four years.

However, the remainder of our carbon footprint will still need to be addressed through genuine energy reduction; and a key step for us is to transition to LED lighting. We are now in the final stages of completing the installation, with the help of a grant which will cover about 10% of the cost.

We also need to look at changes in our behaviour; and here the challenge truly begins. Our first step will be exploring our staff’s existing environmental attitudes and behaviours (such as how they travel to work). As the winter months approach, and at a time when individuals and businesses are all under financial pressure, we are going to need to be creative about how to cut both carbon and costs.